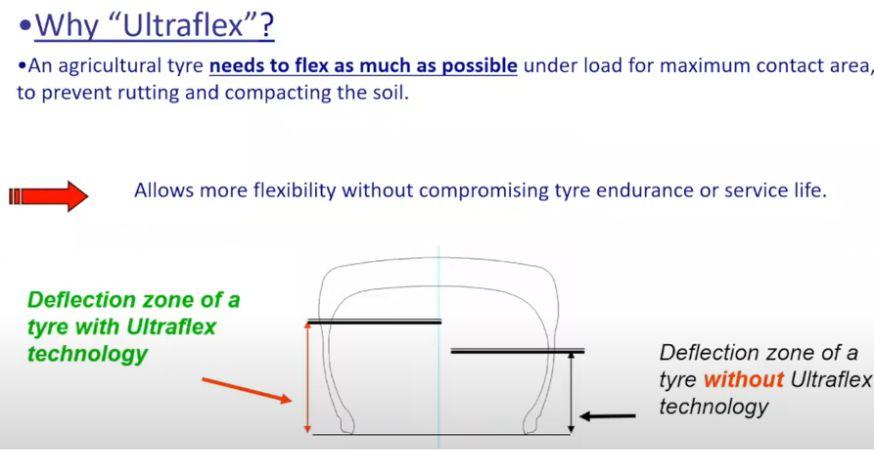

We see increasing publicity about the crop yield and performance benefits of IF and VF tyres – where IF and VF denote ‘Increased Flexion’ and ‘Very High Flexion’, respectively. These tyres have more flexible sidewalls, which allow lower pressures and greater contact areas for tyres of the same nominal size Fig. 1).

For most practical purposes, compared with standard tractor tyres of corresponding section width/rim size designation:

- IF (Increased Flexion) tyres can carry the same load at 20% less pressure or 20% more load at the same pressure.

- VF (Very High Flexion) tyres can carry the same load at 40% less pressure or 40% more load at the same pressure.

- PFO (Pressure Field Operation) enables tractor IF/VF tyres to bear a higher load at a lower speed.

- CFO+ tyres are designed to provide additional load capacity in the field for up to 1.5 km of travel at the maximum load.

VF tyres offer less restrictive road travel speeds, which can be advantageous in certain applications. Nevertheless, central tyre inflation systems (CTIS) remain essential for situations where higher load capacity is required during low-speed fieldwork or for vehicles frequently switching between high-speed road travel and fieldwork.

The positive yield effects of IF tyres have been demonstrated in projects in both the UK and USA where IF tyres with 20% less tyre pressure produced almost 4% greater yield, which generously repaid their additional cost, even on relatively small grain farms. The caveat is that these results were found in non-CTF, tillage-based grain systems with 70% wheeled area, and with low pressure in all tyres on all field equipment.

The UK tyre pressure trial also included a CTF treatment, and grain yields under CTF were greater in all but two of the eight years of the trial. The overall average yield improvement from this CTF system, with 30% of crop area wheeled was 4%, but that yield improvement would have been 7% if wheeled area was 15%. No compaction is still a substantial improvement on reduced compaction!

The US experiment in Iowa considered the effect of VF tyres with 50% lower pressures on all except the header (which had 25% reduction). Compared with standard tyre pressures, the average yield benefit of low-pressure over three years was 3.5% and 2% for maize and soybean respectively. Low-pressure tyres also had the greatest effect in systems based on deep, rather than standard or no-tillage. Again, increased yield more than paid for the additional tyre costs, but there was no CTF comparison in the US work.

The UK tests continued for eight years, and over this period yields from no-till improved steadily relative to the tilled treatments and no till produced the best yields in the final two years. The US work showed that yields from no-till were generally less than those following deep tillage, but this work continued for only three years. It would be nice to think work was continuing, to see if it replicates Australian experience of a yield reduction in the first years of no-till, followed by a steady improvement over time.

In the UK at least, low-pressure IF/VF tyres are being advertised partly on the basis of the benefits for crop yields. It’s also likely that these effects are greater in the tillage-based systems commonly used in that environment. Might they be a good investment for Australian CTF growers?

- IF/VF tyres give you the option to reduce pressures, improving performance while carrying the same load. This is important in marginal conditions, expanding the window of operation for some jobs. Alternatively, a greater load can be carried at the same pressure.

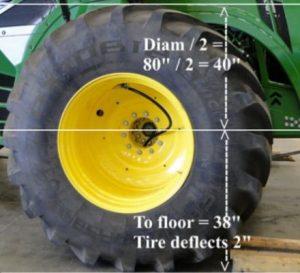

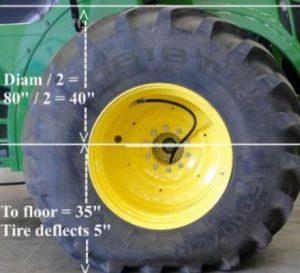

- Reducing tyre pressure for the same load increases the area of the of the tyre footprint largely by increasing footprint length* (Fig 2). The longer footprint is a positive for tractive efficiency and doesn’t increase wheeled area because the increased footprint is gained without making a wider track.

These are all benefits, on the other hand:

- IF/VF tyres cost 20-30% more than the equivalent standard tyre. This would almost certainly be repaid over time by the performance improvement and there is evidence of longer operating life.

- As with any tyre, optimum performance depends on everything being right: a rim that’s too narrow, for instance can produce problems.

The isolation of soil compaction into permanent traffic lanes is a fundamental feature of CTF, but this doesn’t mean you can ignore the role of impact of tyres in your farming operation. New tyre designs have a lot to offer in terms of operating cost and efficiency, and regardless of the choice of CTF or non-CTF, growers should consider if the benefits offered warrant their use. It will be interesting to hear some practical experience with low-pressure tyres from Australia.

*More flexible sidewalls with a stiff belt under a relatively flat tread profile ensure minimal change in the footprint width unless the sidewall bulge is touching the soil – which happens only if you’re nearly bogged!

Fig. 1. Schematic of flex capability in IF/VF tyres compared to radial tyres. (Image: Michelin)

Fig. 2. Illustration of IF 800/70R34 with small deflection, optimal for transport (left) and large, long footprint, optimal for field work (right). (Image: Precision Inflation)